HELIDECK NETTING

Home / Products / Height Safety / Helideck Netting

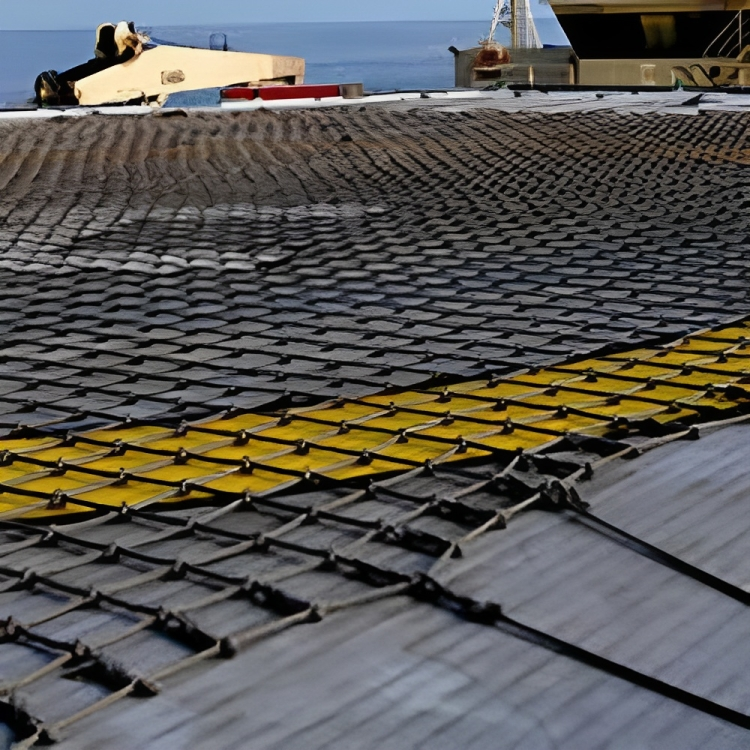

Helideck Landing Net Manila / Sisal rope

Helideck Landing Nets, where safety and precision are paramount in our helicopter landing solutions. Our meticulously crafted nets have been specifically designed to ensure secure landings in high-risk areas, including offshore platforms, ships, leisure yachts, and rooftop helipads.

Manufactured in the UK with a commitment to excellence, our Helideck Landing Nets offer bespoke solutions that prioritize safety and durability. Our Helideck Landing Nets stand as a testament to our commitment to safety, quality, and innovation in helicopter landing solutions. Explore the difference that precision engineering can make in critical operations with helideck nets.

Our Helideck Landing Nets find versatile applications across industries, including:

- Offshore Energy: Ensuring safe and controlled helicopter landings on offshore platforms for oil and gas operations.

- Maritime: Providing critical safety measures for helicopter landings on ships and leisure yachts.

- Emergency Services: Supporting efficient helicopter landings during emergency response operations.

- Construction and Infrastructure: Enhancing safety for helicopter landings in construction sites and rooftop helipads.

Our Helideck Landing Nets are available in various standard sizes to accommodate different helicopter types and landing areas:

- Small: 9 meters by 9 meters

- Medium: 12 meters by 12 meters

- Large: 15 meters by 15 meters

The weight Helideck Landing Nets is optimized for easy handling and installation, ensuring practicality in various environments. Specific weight details can be provided upon customization to meet client requirements.

- Safety Assurance: The Helideck Landing Nets play a vital role in ensuring safety by acting as a crucial barrier to prevent helicopter skidding and ensure secure landings in high-risk environments.

- Customization: Our nets are carefully crafted to meet the specific needs of our clients, providing a customized solution that guarantees the highest level of safety and performance for every landing area.

- Durability: Constructed with high-quality manila or sisal rope, our nets withstand the most severe offshore weather conditions and ultraviolet radiation, ensuring long-lasting durability.

- Bespoke Design: Expert technicians craft the nets according to client specifications, offering a low profile knotless design of 12mm or 20mm diameter Manila or Sisal rope.

- CAP 437 Compliance: Meeting international safety standards, our nets adhere to CAP 437 Standards for Offshore Helicopter Landing Areas, Chapter 3 7.3, ensuring regulatory compliance.

- Quality Control: Every Helideck Landing Net undergoes a rigorous quality control process, guaranteeing the correctness of every weave before packaging and transport.

- Versatile Sizing: Available in standard sizes, with the option for square, circle, or octagonal shapes at no extra cost, providing flexibility to suit diverse landing area requirements.

Helideck Perimeter Netting

Helideck Perimeter Netting, where safety and precision converge to create a secure workable environment within the Helideck Landing Area. Our bespoke manufacturing ensures that the nets are tailored to meet individual Helideck Perimeter requirements. Designed for durability and compliance, these nets provide a safe operating environment for all personnel within the helideck area. Our Helideck Perimeter Netting is your trusted solution for creating a safe and secure environment within the helideck landing area, combining durability, compliance, and precision engineering for optimal safety outcomes.

FEC Helideck Perimeter Netting plays a critical role in various industries, offering a secure environment for personnel in the following applications:

- Offshore Energy: Ensuring safety on offshore platforms during helicopter operations.

- Maritime: Providing a safe operating space on ships with helipads.

- Emergency Services: Creating a secure environment for helicopter landings during emergency response operations.

- Construction and Infrastructure: Enhancing safety on construction site helipads.

The dimensions of our Helideck Perimeter Netting are customized to meet the unique requirements of each helideck, providing a precise and tailored solution for perimeter safety.

The netting is designed with a balance of weight to ensure easy installation while maintaining robustness. Specific weight details can be provided upon customization to meet client requirements.

- Safety Assurance: FEC Helideck Perimeter Netting creates a safe workable environment within the helideck landing area, ensuring the safety of all personnel during helicopter operations.

- Bespoke Manufacturing: Tailored to meet individual helideck perimeter requirements, our nets are manufactured to fit securely onto perimeter frames using high-quality polyester webbing.

- Compliance: The polyester material used in our nets meets the latest safety standards, including BS EN 1263-1, CAP437 December 2016 8th Edition, OGUK & CAA/ICOA for perimeter nets. The material’s surface resistance levels comply with BS NCB 245:1985 Appendix 5.

- Long Working Life: With an anticipated working life of 7-10 years in the Northern European Environment, the nets remain durable and effective with regular inspections, meeting CAP 437 regulations.

- Secure Fastening: Helideck Perimeter Nets are securely fastened onto perimeter frames using our reliable polyester webbing, ensuring stability and longevity.

- Tested Material: Polyester material undergoes rigorous testing by independent test houses to meet the highest safety standards, providing confidence in its reliability.

- Comprehensive Inspection: Regular inspections, including stretch tests and visual inspections, ensure the ongoing effectiveness of the nets in compliance with CAP 437 regulations.

- Compliance with Regulations: The nets are designed and tested to meet the requirements set out in CAP 437 regulations for helideck perimeter safety netting, ensuring regulatory compliance.