Explosive environments demand meticulous consideration when it comes to lighting solutions. In this blog post, we’ll delve into the critical decision-making process of choosing between High Bay and Low Bay Explosion Proof LED options. Understanding their unique characteristics and applications is essential for creating a safe and efficient lighting environment in hazardous areas.

A Comprehensive Comparison Between High vs Low Explosion Proof LED

|

Comparison Parameters |

High Bay |

Low Bay |

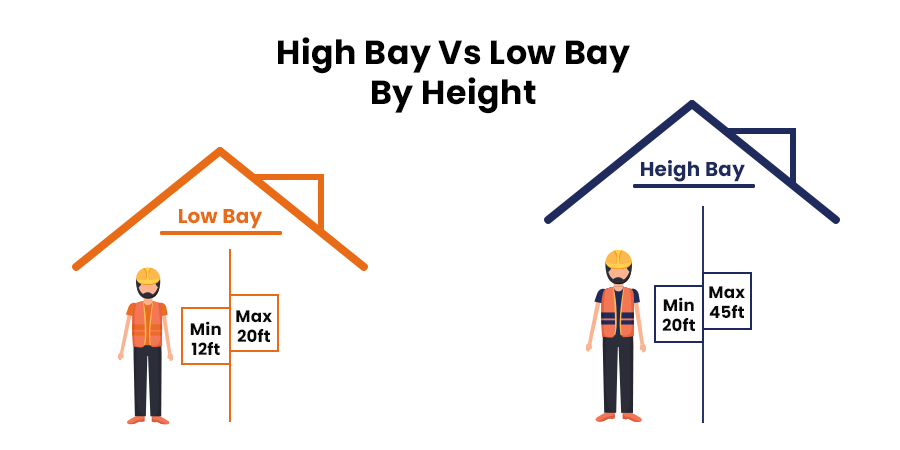

| Ceiling Height Considerations | Designed for ceilings exceeding 20 feet, providing optimal illumination in large, open spaces. | Tailored for ceilings below 20 feet, ensuring effective lighting in areas with lower clearance. |

| Light Distribution and Coverage | Offers broad, uniform illumination over a large area, making it suitable for warehouses, manufacturing plants, and high-ceiling spaces. | Provides focused lighting for smaller, more confined spaces, ensuring adequate brightness without unnecessary spillage. |

| Energy Efficiency | Typically more energy-efficient in large spaces due to their ability to cover expansive areas with fewer fixtures. | Offers efficiency in smaller spaces, preventing over-illumination and minimizing energy consumption. |

| Cost Considerations | Initial costs may be higher due to the powerful luminosity and broader coverage. However, long-term savings may be realized in larger spaces. | Generally more cost-effective for smaller areas, with a more straightforward installation process. |

| Installation Height and Maintenance | Installed at greater heights, requiring specialized equipment for maintenance. However, the reduced frequency of maintenance compensates for the challenges. | Installed at lower heights, facilitating easier maintenance but may require more frequent attention in certain applications. |

| Safety Compliance | Designed to meet safety standards for high-ceiling environments, ensuring compliance in industrial settings. | Adheres to safety regulations for spaces with lower ceilings, addressing the specific needs of confined areas. |

How to Choose the Right Explosion Proof Bay Lighting

Choosing the right explosion-proof bay lighting is crucial for ensuring safety and optimal illumination in hazardous environments. Here’s a step-by-step guide to help you make an informed decision:

1.) LED vs. Fluorescent Bulbs: Illuminating the Future

In the ever-evolving realm of lighting, the battle between LED and fluorescent bulbs has a clear winner. LED sales soared past 10 billion units in 2019, officially dethroning fluorescent lamps as the go-to option. The reasons behind this surge are compelling – LED lights outshine their counterparts by lasting 25 times longer, consuming 75% less energy, and boasting hassle-free installation. Not only do they illuminate your space, but they also illuminate your savings, offering rebates and reduced energy and disposal costs.

2.) High Bay vs. Low Bay LED Lighting: Decoding the Ceiling Height Puzzle

When it comes to lighting up large spaces, the decision between high bay and low bay LED lighting hinges on your ceiling height and the nature of the area you wish to illuminate. Measure your ceiling height and choose wisely between these two lighting titans to ensure optimal brightness and coverage.

3.) Beam Angle and Width: Shedding Light on Precision

The right beam angle can make all the difference. Choose from options like 60°, 90°, or 120° for high bay lighting fixtures, ensuring it aligns with your ceiling height. Calculate the beam width using a simple formula (beam angle x 0.018 x distance from the light bulb) for precision illumination.

4.) Mounting and Distributing Options: Setting the Stage

Your lighting setup’s foundation lies in the mounting options – slip filters, trunnions, and straight arms. Choose wisely based on your needs. Opt for the right light distribution pattern – Type III for parking lots and Type V for broader coverage in various spaces.

5.) Retrofitting: Bridging the Gap to Efficiency

Retrofitting kits, bundled with most LED fixtures, offer a cost-effective and time-saving solution. If your current lights are in good condition but need an energy-efficient upgrade, retrofitting kits are your illuminating saviors.

6.) Power: Illuminating Every Nook and Cranny

The power of your lighting fixture is paramount. Look for fixtures with a minimum of 130 lumens per watt to ensure they illuminate every inch of your space effectively.

7.) Color Temperature: Finding Your Light’s Persona

Selecting the right color temperature is an art. Warmer hues provide comfort, while blues enhance visibility. Strike the perfect balance based on your space’s ambiance and requirements.

8.) Shape: Lighting Geometry

Consider the shape of your lighting fixture. Round lights are versatile, illuminating vast spaces, while rectangular lights are perfect for focused lighting on workbenches and production lines.

9.) Energy Usage: Smart Lighting for Sustainability

LED lights inherently reduce energy consumption, but additional components can amplify these savings. Integrate dusk-to-dawn photocells, motion sensors, and dimmers to ensure your lights operate at full power only when needed, enhancing both efficiency and sustainability. Illuminate smartly, illuminate responsibly!

Conclusion

Choosing LED over fluorescent bulbs emerged as the optimal path, offering longevity, energy savings, and ease of installation. This choice, coupled with considerations like beam angle, retrofitting, and color temperature, paves the way for a future where lighting is both smart and sustainable.

Now, as you embark on selecting the right explosion-proof bay lighting, consider FSE SAFE as your trusted partner. Our commitment to safety and cutting-edge technology makes us the ideal choice for your illumination needs in hazardous areas.