COMBUSTIBLE GAS DETECTOR

VECTOR- COMBUSTIBLE

The Vector represents a cutting-edge point gas detector equipped with a local display feature. It boasts the flexibility to monitor up to two sensors, either directly connected or remotely installed at distances of up to 500 ft. When it comes to combustible detection, the Vector offers versatility by accommodating plug-in sensors, including options for Infrared (IR) or catalytic bead types.

In terms of communication, the unit is equipped with multiple output options, allowing users to connect via 4-20mA, RS485, or relay for reliable integration into their systems. Calibration is made convenient through on-site, non-intrusive processes facilitated by the local display or HART handheld devices. The on-board memory maintains an event log, ensuring calibration records and diagnostics are securely stored.

The Vector serves as a versatile display unit, capable of receiving signals from all ESP Safety gas detectors, including SGOES, TGAES, and PGU. The OLED display provides a vivid representation of gas type, real-time concentration, and alarm levels. Housed in durable stainless steel, the detector combines advanced functionality with robust construction.

The product is capable of being configured to accommodate 2 detectors, allowing for cost savings by monitoring 2 different gases in a single location or utilizing one display for 2 separate locations.

The event data log is stored in the on-board memory and can be accessed via the display or RS-485 Modbus RTU.

The OLED screen is able to simultaneously display a wide range of data, including gas concentrations, alarm levels, faults, and operational modes.

Furthermore, the product is backed by a 5-year warranty, ensuring a long product life with minimal operating costs over time.

Power Requirements: 24VDC Nominal (18 to 32VDC)

Power Consumption: 4.3 W-Standby; 5.3 W-During Alarms; 12.0 W-w/ Heater On (temp ≤ 30°F)

Signal Output From Vector FCU: 2x +4-20mA analog output, Digital RS-485 Modbus RTU, Relays, HART

Alarm Relays:

3 User Programmed Alarm Relays (factory default setting: NO)

1 Fault Condition Programmed Relay (factory default setting: NC)

Ingress Protection: IP66/67

Operating Temperature: -58°F to +167°C (-50°C to +75°C) -76°F to +167°C (-60°C to +75°C) with heater enabled

Storage Temperature: -76°F to +185°C (-60°C to +85°C)

Humidity Range: 0 to 100% Relative Humidity, Non-Condensing

Conduit Connection: ¾” NPT

2 Connections for Sensors

2 Connections for Field Wiring

Enclosure Material: Stainless Steel (Grade 316L) or Aluminum

Dimensions: 7.50” x 5.60” x 4.28” (190.5mm x 142.24mm x 108.71mm)

Weight: Vector with one PGU attached – 14.00 lbs (6.35 kg)

- Dual Sensor Monitoring: Up to two sensors for direct or remote installation.

- Combustible Detection: Supports IR or catalytic bead plug-in sensors.

- Communication Options: 4-20mA, RS485, and relay for system integration.

- Easy Calibration: On-site calibration via local display or HART device.

- Event Log: On-board memory for calibration records and diagnostics.

- Multi-Use Display: Compatible with various ESP Safety gas detectors.

- Stainless Steel Housing: Durable for harsh environments.

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

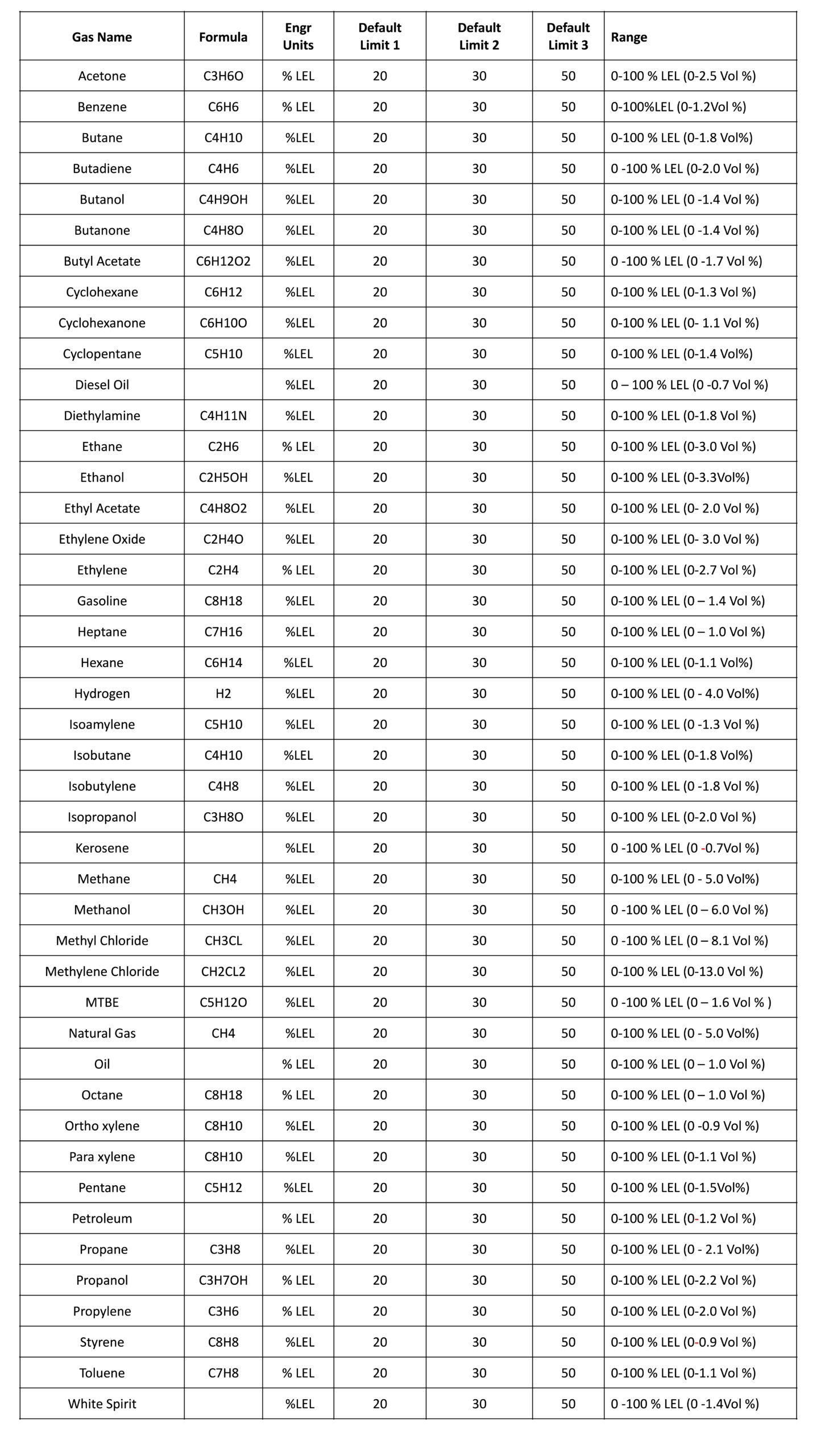

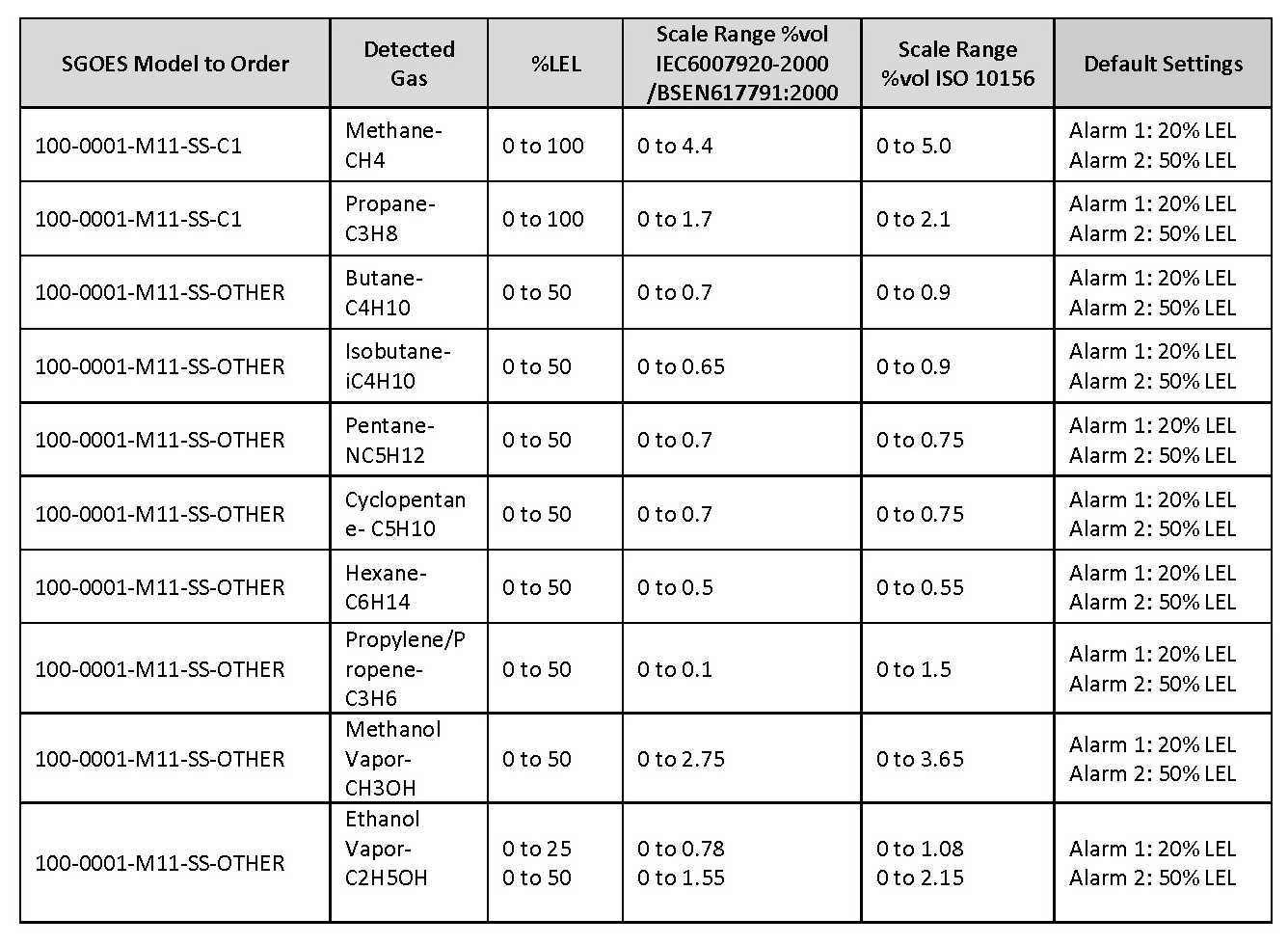

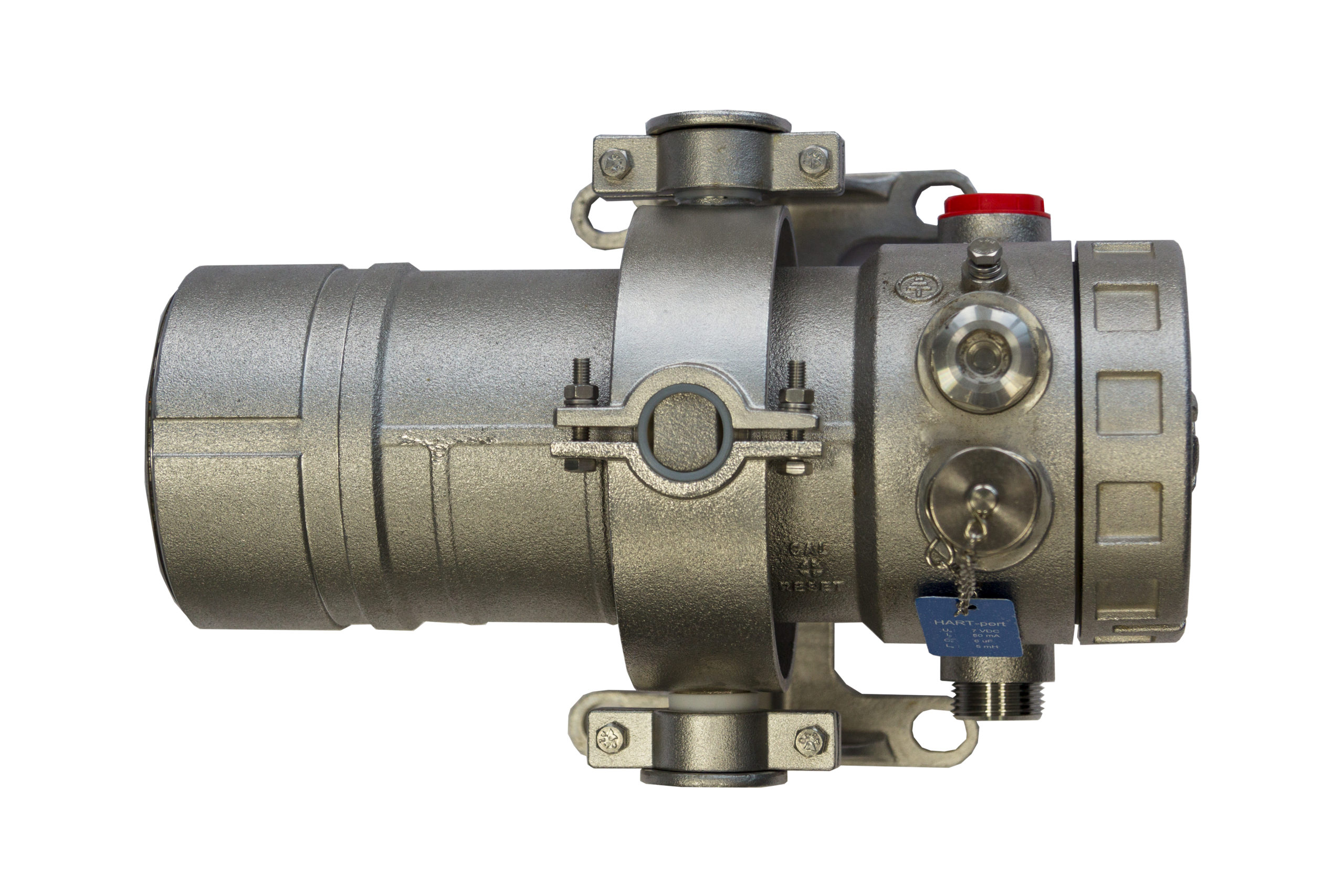

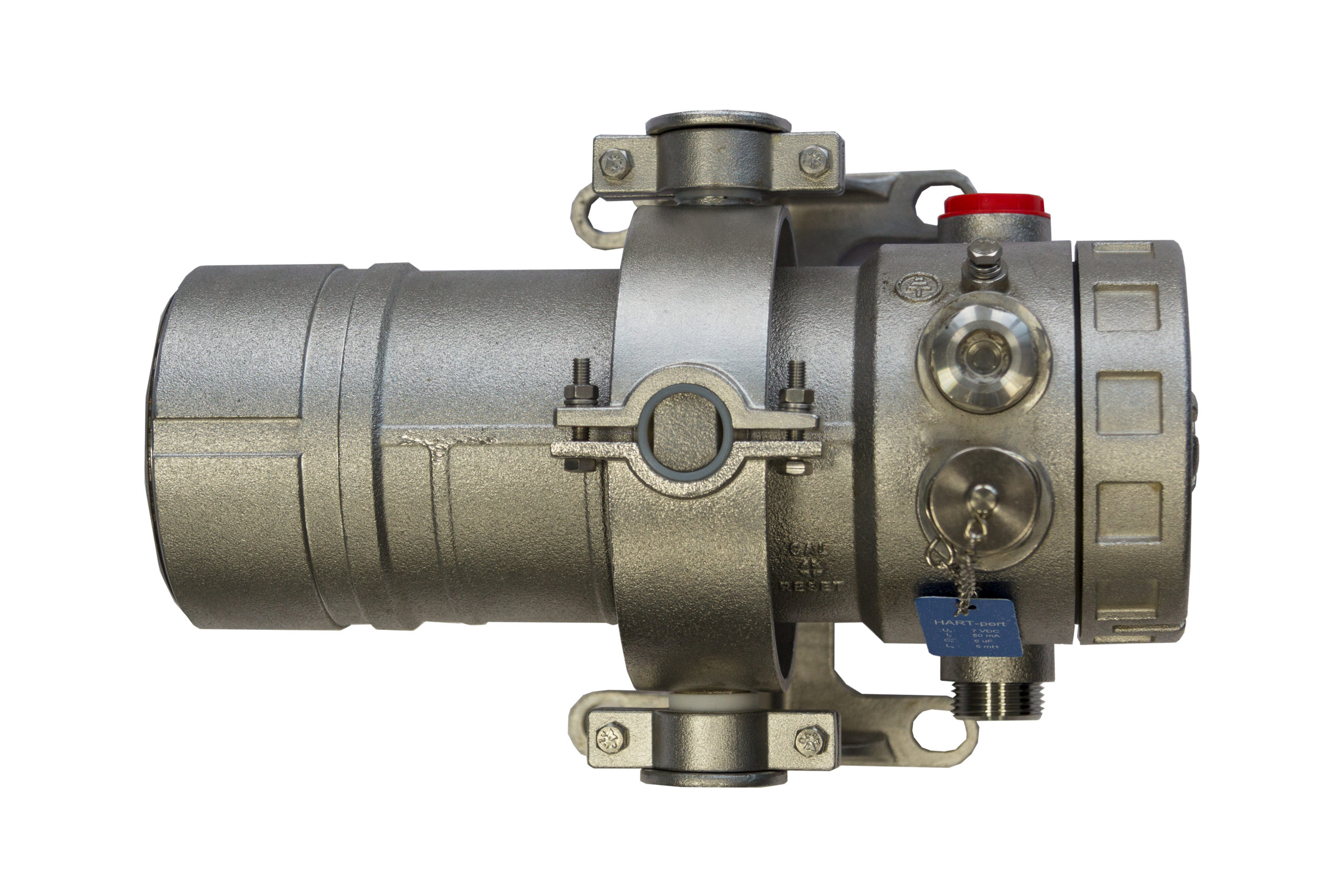

SGOES

The SGOES Gas Detector is designed to accurately measure the concentration of hydrocarbon gases in a monitored environment. Using infrared light (IR), its sensor detects and quantifies hydrocarbons, expressing concentrations as a percentage of the lower explosive limit (LEL) in the air. Two programmable alarm levels provide timely alerts.

Equipped with a continuous self-check function, the detector notifies users of any obstruction in its field of view or circuit integrity issues. Multiple output options (4-20mA, RS485, or system relay) ensure reliable communication. To address condensation concerns, an internal heater prevents damage, while the device’s low power consumption (less than 4.5W) ensures cost-effective operation.

The SGOES facilitates a seamless on-site non-intrusive calibration process through a magnetic wand or a HART handheld device, requiring calibration only every two years, highlighting its reliability. Unlike some sensors, it doesn’t rely on the presence of oxygen and is not sensitive to gases like nitrogen, oxygen, carbonic acid, ammonia, or hydrogen sulfide, making it ideal for environments with non-hydrocarbon gases. Available in both stainless steel and aluminum housing, the SGOES Gas Detector is a robust and versatile choice for monitoring hydrocarbons in diverse settings.

Fast Response –High sensitivity to all hydrocarbon gases/vapors within 1-2 sec

Wide Operating Temperature –Makes SGOES great choice for challenging applications from -60°C to +90°C

2 year Calibration Interval –The longest industry interval between calibration is 2 years

5 year warranty –Long product life with low cost to operate over time

Power Requirements: 24VDC nominal (18-32VDC range)

Power Consumption: 7.9W maximum

Signal Outputs: +4-20mA, Digital RS485 MODBUS RTU, HART, Relays

Alarm Relays:

2 User Programmed Alarm Relays (factory default setting: NO)

1 Fault Condition Programmed Relay (factory default setting: NC)

Gas Detection Range: 0-100% LEL

Accuracy: ± 2% of the full-scale gas concentration

Response Time (for 100% LEL methane):

50% full scale < 1.5 seconds

90% full scale < 2.0 seconds

Ingress Protection: IP66

Operating Temperature: -76⁰ F to +185⁰ F (-60⁰ C to +85⁰ C)

Storage Temperature:

Humidity Range: Up to 95% relative humidity, non-condensing (Withstands up to 100% relative humidity for short periods)

Conduit Connection: ¾” NPT

2 connections for Field Wiring

1 connection for HART/USB

Enclosure Material: Stainless Steel (Grade 316L) or Aluminum

Dimensions: 8.01” x 5.30” x 5.12” (203.5mm x 134.50mm x 130mm)

Weight: 14.33lb (6.5 kg)

- Drilling and production platforms

- Shipping tankers, freighters, and other vessels

- Fuel loading facilities

- Refineries, bulk terminals, and tank farms

- LNG/LPG processing and storage facilities

- Compressor stations and pipeline facilities

- Petrochemical, paint, and fertilizer plants

- Power plants and gas turbine facilities

- Transportation facilities (airports and subways)

- Oil and gas fired boilers / furnaces • Environmental regulation monitoring

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

TGAES

The TGAES Gas Detector is an advanced open-path infrared system for continuous monitoring of combustible hydrocarbon gas concentrations. Operating effectively over 15 to 650 feet without a direct electrical connection, it uses a transmitter emitting infrared light to detect gases intersecting the beam. The system incorporates two heaters for durability, a self-check function, and offers 4-20mA, RS485, or relay outputs for versatile integration. Housed in stainless steel, it excels in perimeter monitoring, ensuring safety in areas prone to combustible gas leaks.

The longest detection range –Monitors a path distance of up to 650ft (200m).

Operates at any outdoor conditions –TGAES distinguishes hydrocarbon gas even when obscured by rain, fog, dust, snow or blowing sand.

Easy Alignment –Use HART communicator or software via RS485 for the fine alignment.

3 year warranty – Long reliable product life, low cost to operate over time

Power Requirements: 24VDC Nominal (18 to 32 VDC)

Power Consumption: Transmitter 15 W, Receiver 15 W*

*low power consumption version available upon request

Signal Outputs: 4 to 20mA analog, Digital RS-485 MODBUS RTU, HART, Relays

Factory Default Settings:

Normally Open

Normally Closed

Alarm Relays:

2 User Programmed Alarm Relays (Factory Default Setting: NO)

1 Fault Condition Programmed Relay (Factory Default Setting: NC)

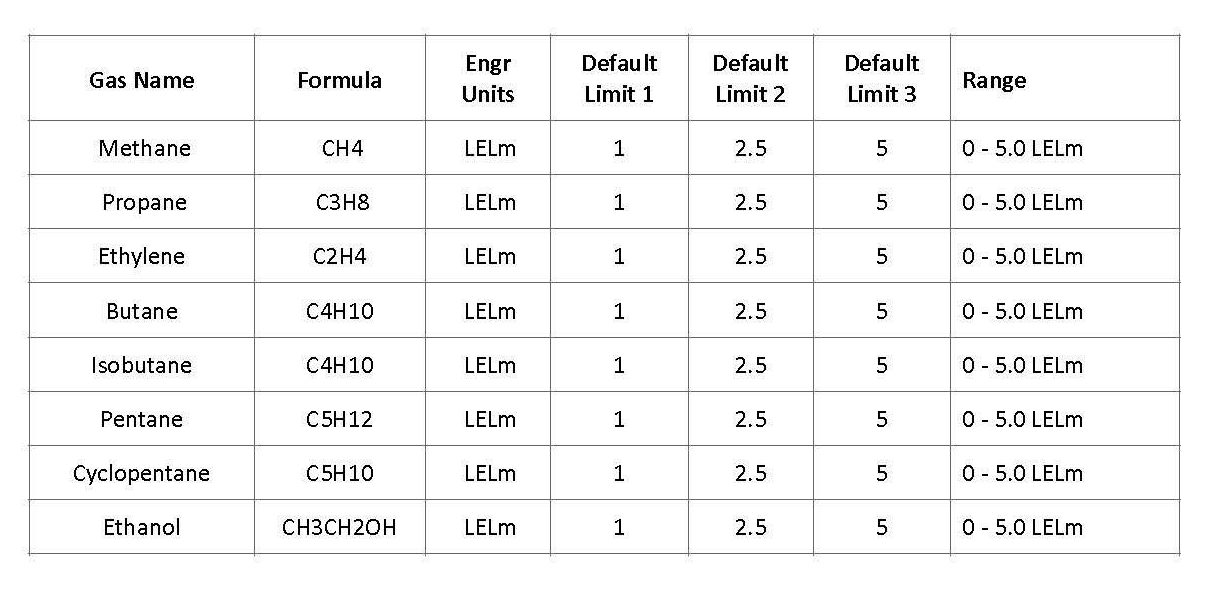

Gas Detection Range: 0 to 1 LEL•m, 0 to 2.5 LEL•m, 0 to 5 LEL•m (Factory Default Setting)

Measuring Distance: 15 ft to 650 ft (5m to 200m)

* A set of apertures, mounted on the transmitter, is provided for operation at distances less than 60m

Ingress Protection: IP66

Operating Temperature: -40⁰ F to +140⁰ F (-40⁰ C to +60⁰ C)

Storage Temperature: -40⁰ F to +140⁰ F (-40⁰ C to 50 °C)

Humidity Range: Up to 100% Relative Humidity, Non-Condensing (withstands up to 100% realtive humidity for short periods)

Conduit Connection: 2 Cable Entries, ¾” NPT

Enclosure Material: Stainless Steel (Grade 316L)

Dimensions: 10.43” x 6.96” x 7.17” (262mm x 176mm x 182mm)

Weight: 16.5lb (7.5kg), Each Module w/ Bracket

- Power stations and storage facilities

- Tank ships and other vessels

- Refineries, bulk terminals, tank farms

- LNG/LPG processing and storage

- Chemical, paint and fertilizer plants

- Power plants and gas turbines

- Transportation facilities

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.