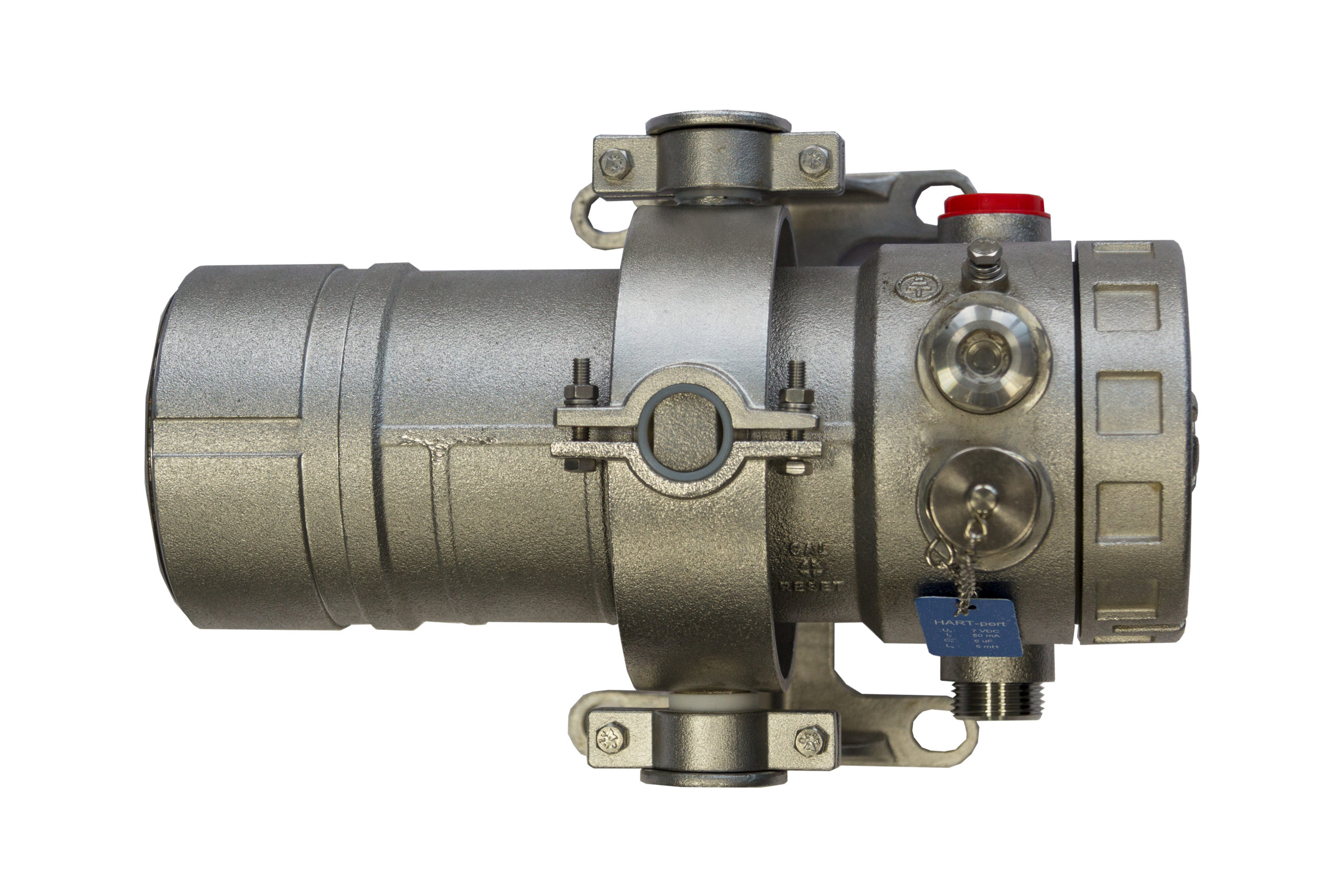

FLAME DETECTOR

IPES IR3

The ESP Safety IPES-IR3 Flame Detector utilizes advanced multi-spectral infrared technology for precise flame detection. Its algorithm minimizes false alarms by confirming flame presence through specific IR wavelength ratios. The detector has a self-check function, multiple output options, and an internal heater for condensation scenarios. With low power consumption and a SIL 3 rating, it offers reliable and high-performance flame detection in diverse applications. Available in stainless steel and aluminum housing, with an extended temperature range from -60°C to +125°C.

Multi-spectral IR detection -The highest level of flame and fire sensitivity

Low Power Consumption -Power consumption of <3W means low power cost

Long Detection -Detection Range of 210 feet maximizes protection area

5 Year Warranty -Long reliable product life, low cost to operate over time

Power Requirements: 24VDC nominal (18 to 32VDC range)

Power Consumption: 3W maximum 3VA

Signal Outputs: +4 to 20mA, Digital RS485 Modbus, Relays.

*All Relays Contact Rating 1 Amp@125VAC/30VDC

Factory Default Relays Settings:

•Fire Relay: Normally Open, Closed on Fire Detection, Non-Latching

•Fault Relay: Normally Closed, Open on Fault Detection, Non-Latching

Detection Response Time: 4.5 to 7 seconds

Detection Distance: Up to 211ft (65m) depending on detected fuel

Detection Field of View: Up to 90° (45° Left/Right of center)

Ingress Protection: IP66

Operating Temperature: ‐40°F to +185°F (‐40°C to 85°C)

Extended Operating Temperature: ‐76°F to +257°F (‐60°C to 125°C)

Storage Temperature: ‐76°F to +185°F (‐60°C to 85°C)

Humidity Range: 0 to 98% relative humidity (can withstand 100% condensing humidity for short periods of time)

Conduit Connection: Two (2) M20 X 1.5, adaptable to ¾” NPT

Enclosure Material: Stainless Steel (Grade 316) or Aluminum (coated)

Dimensions: 9.08″X 14.20″X 3.94″ (231mm X 361mm X 100mm) mounted with bracket

Weight: Stainless Steel 13.2lb (6.0kg), Aluminum 7.7lb (3.5kg)

- Offshore drilling and production platforms

- Vessels for shipping, including tankers and freighters

- Facilities dedicated to fuel loading

- Refineries, tank farms, and bulk terminals

- Facilities for processing and storing LNG/LPG

- Compressor stations and pipeline facilities

- Plants involved in petrochemicals, paint, and fertilizer production

- Power plants and facilities equipped with gas turbines

- Transportation centers like airports and subway stations

- Boilers and furnaces utilizing oil and gas as fuel

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

IPES IR/UV

The IPES-IR/UV Flame Detector is designed for heightened sensitivity in detecting oil and petrochemical fires, using integrated UV and IR sensors with a 90-degree field of view. Multiple sensors minimize false alarms from non-flame radiation sources. The detector has a self-check function, multiple output options, and an internal heater for condensation. With less than 3W power consumption, it offers cost-effective operation. Available in stainless steel and aluminum housing for diverse environments.

Positive Alarm Confirmation -Combines both IR and UV sensor configuration to declare a Fire Alarm

Fast Response Time -Rapid flame recognition within 4 seconds

5 Year Warranty-Long reliable product life, low cost to operate over time.

Detection range 100 feet -Recognizes the flame within 100 feet distance.

- Power Requirements: 24VDC nominal (18 to 32VDC range)

- Power Consumption: 3W maximum 3VA

- Signal Outputs: +4 to 20mA, Digital RS485 Modbus, Relays.

*All Relays Contact Rating 1 Amp@125VAC/30VDC - Factory Default Relays Settings:

•Fire Relay: Normally Open, Closed on Fire Detection, Non-Latching

•Fault Relay: Normally Closed, Open on Fault Detection, Non-Latching

Detection Response Time: 4.55 to 5 Seconds

Detection Distance: Up to 100ft (30m) depending on detected fuel.

Detection Field of View: Up to 90° (45° Left/Right of center)

Ingress Protection: IP66

Operating Temperature: ‐40°F to +185°F (‐40°C to 85°C)

Storage Temperature: ‐76°F to +185°F (‐60°C to 85°C)

Humidity Range: 0 to 98% relative humidity (can withstand 100% condensing humidity for short periods of time)

Conduit Connection: Two (2) M20 X 1.5, adaptable to ¾” NPT

Enclosure Material: Stainless Steel (Grade 316) or Aluminum (coated)

Dimensions: 9.08″X 14.20″X 3.94″ (231mm X 361mm X 100mm) mounted with bracket

Weight: Stainless Steel 13.2lb (6.0kg), Aluminum 7.7lb (3.5kg)

- Drilling and production platforms

- Shipping tankers, freighters, and other vessels

- Fuel loading facilities

- Refineries, bulk terminals, and tank farms

- LNG/LPG processing and storage facilities

- Compressor stations and pipeline facilities

- Petrochemical, paint, and fertilizer plants

- Power plants and gas turbine facilities

- Transportation facilities such as airports and subways

- Oil and gas-fired boilers/furnaces

- Aircraft hangars

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

IPES UV

The IPES-UV Only Flame Detector excels in detecting hydrogen and metal fires with a 90-degree field of view, focusing on 180-250nm UV radiation emitted by flames. It features a continuous self-check function, multiple output options, and an internal heater for condensation prevention. With less than 3W power consumption, it ensures cost-effective energy use. Available in stainless steel and aluminum housing for versatile applications requiring superior flame detection.

Fastest Response Time – The response time within 1-2 seconds ensure rapid flame recognition and alarm signaling

5 Year Warranty -Long reliable product life, low cost to operate over tim

Hydrogen Fires – Ideal for detection of hydrogen fires

Metal and Pyrophoric Fires -Optimal detection of metal and pyrophoric based fires

Power Requirements: 24VDC nominal (18 to 32VDC range)

Power Consumption: 3VA (3 Watt) Max

Signal Outputs: +4 to 20mA, Digital RS485 Modbus, Relays.

*All Relays Contact Rating 1 Amp@125VAC/30VDC

Factory Default Relays Settings:

•Fire Relay: Normally Open, Closed on Fire Detection, Non-Latching

•Fault Relay: Normally Closed, Open on Fault Detection, Non-Latching

Detection Response Time: 1 to 2 seconds

Detection Distance: Up to 100ft (30m) depending on detected fuel.

Detection Field of View: Up to 90° (45° Left/Right of center)

Ingress Protection: IP66

Operating Temperature: ‐40°F to +185°F (‐40°C to 85°C)

Storage Temperature: ‐76°F to +185°F (‐60°C to 85°C)

Humidity Range: 0 to 98% relative humidity (can withstand 100% condensing humidity for short periods of time)

Conduit Connection: Two (2) M20 X 1.5, adaptable to ¾” NPT

Enclosure Material: Stainless Steel (Grade 316) or Aluminum (coated)

Dimensions: 9.08″X 14.20″X 3.94″ (231mm X 361mm X 100mm) mounted with bracket

Weight: Stainless Steel 13.2lb (6.0kg), Aluminum 7.7lb (3.5kg)

- Refineries, bulk terminals, and tank farms

- Compressor stations and pipeline facilities

- Power plants and gas turbine facilities

- Transportation facilities (airports and subways)

- Oil and gas fired boilers/furnaces

- Aircraft hangars

- Paint Booths

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.