Ex Ventilation

Fans

Home / Products / Ex Ventilation / Ex Vent Fans

Ex Bug Blower Fan

In high-risk environments where hazardous gases pose a constant threat, the safety and well-being of personnel are of utmost importance. Introducing the Ex Bug Blower Fans, a revolutionary solution carefully designed to address the challenges of ventilation and pest control.

These Explosion Proof Bug Blower Fans are invaluable for cooling both personnel and equipment, as well as ensuring the circulation of clean air in the presence of hazardous gases while effectively eliminating insects and bugs.

- The Ex Bug Blower Fans are committed to enhancing air quality and deterring unwanted insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- Providing a comprehensive approach to fostering workplace well-being, prioritizing safety, comfort, and efficiency. The Ex Bug Blower 50 stands out as the preferred option, crafted for use in both onshore and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

- Most Popular for Offshore Drilling Rigs is our FSE_BB50 50″ Ex Proof Bug Blower Fans

- HDG steel casing, exd motor 4

- 6kw, 6p, floor mounted

- 480/3/60 EExdIIBT4 B3

- Anti static blades

- Both steel epoxy coated guards

- Optional Extras – Export-grade wooden box crating ensures secure packing for seaworthy transport. The Ex DOL Starter comes in loose packaging, accompanied by a PE Lifting Certificate for the lifting lugs welded on the top of the casing.

- Enhanced safety

- Improved comfort

- Pest control

- Versatility

- Sizes: Standard sizes include 24″ , 36″ , 48″ and 50″ dia

- Power Supply: Standard includes 110v, 230v, 380v, 400-440-480v

- CFM 25k Standard – Customised from 11k to 65k CFM

- Ex Proof Motor and Optional DOL Starter

- Anti-static blades with test report

- OSHA type Mesh Guard

- Oil and Gas Industry (Onshore and Offshore)

- Chemical Processing Plants

- Refineries

- Mining Industry

- Petrochemical Industry

- Manufacturing and Industrial Plants

- Power Generation Utilities

- Marine Industry (Shipyards, Offshore Platforms)

- Wastewater Treatment Plants

- Food Processing and Storage Facilities

- Agricultural Industry (Farms, Agricultural Facilities)

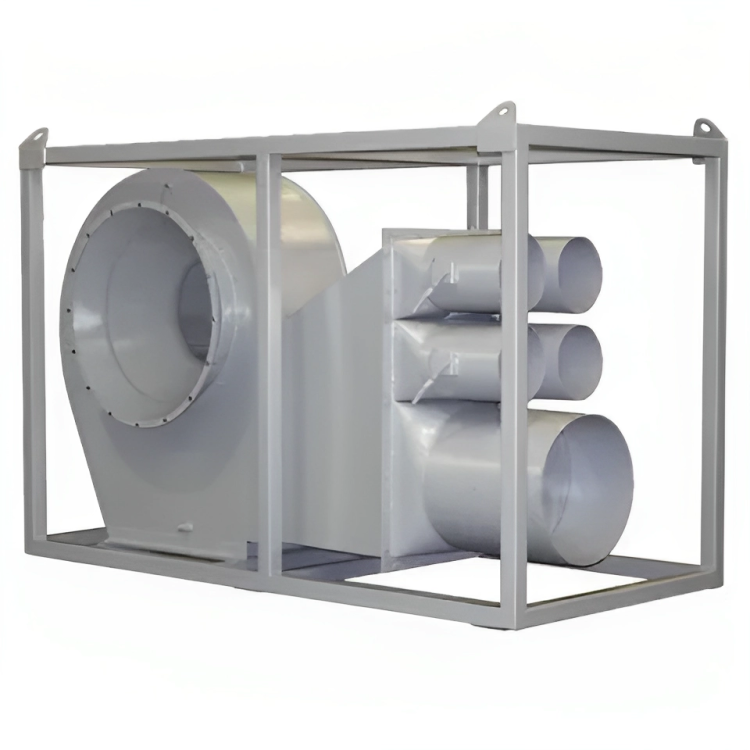

Ex Tank Vent Fans

Introducing our state-of-the-art Tank Ventilation Fans: Engineered for Safety in Hazardous Environments In critical settings such as FPSOs, offshore platforms, tanks, and confined spaces, ensuring optimal ventilation is of utmost importance.

That why we developed our high-performance Tank Ventilation Fans, specifically crafted to excel in these demanding conditions.

Explosion Proof certified Tank Vent Fans are high performance fans with single inlet and multiple outlets and Portable

- Meticulously designed fans meeting stringent ATEX and IECEx Zone 1 & Zone 2 certifications.

- High-Performance Inlet Centrifugal Fan ideal for hazardous environments, ensuring safety with ATEX and IECEx certification.

- Portability allows seamless transportation and versatile deployment on multiple vessels.

- Designed to introduce fresh air into tanks and confined spaces, establishing a secure working environment.

- Highly effective for gas-freeing oil and chemical tanks.

- Single inlet and multiple outlets for remarkable adaptability across a wide range of applications.

- Energy-efficient design results in substantial cost savings on operational expenses.

- Hazardous area portable ventilation fan stands out in tank ventilation solutions for offshore marine environments.

- Trust in tank vent fans to safeguard operations, ensuring peace of mind and uncompromised safety for teams.

- Choose Tank Ventilation Fans for unmatched performance and reliability in hazardous environments, elevating safety standards in the industry.

- High-performance centrifugal fans for exceptional airflow.

- Certified for hazardous areas (ATEX, IECEx Zone 1 & 2).

- Easily portable with lifting lugs for convenient transport.

- Simultaneous ventilation of multiple tanks. Single Inlet and multiple outlets

- Enhances safety by ventilating hazardous areas.

- Meets strict ATEX and IECEx standards.

- Versatile for FPSOs, offshore platforms, tanks, and confined spaces.

- Reliable operation in demanding conditions.

- Offshore Marine

- FPSOs (Floating Production Storage and Offloading)

- Tank Farms

- Confined Spaces

Model Variations

Portable Tank Ventilation Fan 575

Portable Tank Ventilation Fan 575 with 6 Outlets

Portable Tank Ventilation Fan 710

Portable Tank Ventilation Fan 800 with 6 Outlets

Ex Portable Blower Exhauster Ventilation Fans

FSE Exstream series Portable Ventilation Blower / Exhauster Fans for Confined Spaces and Hazardous areas are Made in UK. The only portable ventilation fans in the world we are aware of having dual certification for mechanical and electrical safety standard. The entire unit as a whole is ATEX certified (not just a assembly of ATEX certified parts) as well as IECEx certified electrical as well as mechanical standards.

With the ATEX and IECEx certification, takes any risk away from enduser and onto its manufacturer.

Exstream fans are the market-leading ATEX fan to provide powerful and portable ventilation in hazardous areas – specified for safe and reliable extraction and blowing of dangerous gases and vapors in explosive atmospheres with airflow capability up to 7750m3/hr @ 50Hz and up to 9400m3/hr @ 50Hz.

- Cutting-edge Explosion Proof Portable Blower – Exhauster Ventilation Fans engineered for top safety and exceptional performance.

- Industrial-grade fans purpose-built for effective ventilation in hazardous areas, ensuring safety for personnel and equipment.

- Dual certifications to ATEX and IECEx standards for both electrical and mechanical components.

- Standout model: Ex-stream 400, a compact yet powerful portable ventilation fan with independent dual certification to ATEX and IECEx standards.

- Specifically designed for hazardous areas like Zone 1, excelling with an impressive airflow of up to 7750 cubic meters per hour.

- Low power consumption (less than 8 amps) and minimal noise output (just 49 decibels) for efficiency and user comfort.

- Robust construction options, including mild steel or stainless steel casing, guarantee durability and longevity.

- Versatile voltage options (110V/230V and 3-phase) tailored for diverse applications in hazardous work environments.

- Trust in our range of ventilation fans for reliable and efficient performance, backed by a commitment to the highest safety standards.

- Independently dual certified to ATEX & IECEx

- Easy to use (plug & play) with Integrated stop/start

- Power lead (5m) with plug

- Alternative plugs available on request

- Power supply either 230v or 110v / 50Hz or 60Hz

- Painted C5M Offshore Standard

- Weight 39kg

- 110v motor option FLC 10Amps

- 230v motor option FLC 7Amps

- Top-tier Safety: Certified for hazardous environments.

- Power Versatility: Compatible with various systems.

- Efficient Ventilation: Swiftly removes pollutants.

- Durability: Built for harsh conditions, long-lasting.

- Portable Ventilation

- Hazardous Areas

- Industrial Settings

- Available in 12” and 16”

- Power supply: 110v or 230v 50/60Hz

- Dual Certification ATEX and IECEx for Electrcial and Mechanical compliance

- Painted C5M Offshore Standard

- High Performance outputs from 3850 m3/hr to upto 9400 m3/hr

Model Variations

Ex Stream 300 ATEX IECEx Portable Fan

Ex Stream 400 ATEX IECEx Portable Fan