FSE Ex Bug Blower specific designed for use in Offshore and Marine Applications including Offshore Drilling Rigs, Offshore platforms and FPSOs. As well as Ex Bug Blower fans for Onshore Drilling Rigs.

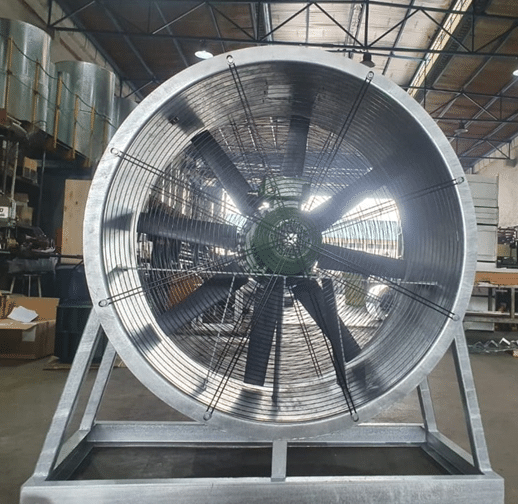

Using HDG Steel for casings of FSE Ex Bug Blower Fans can be ideal choice and provide several advantages:

- Corrosion Resistance: HDG steel is coated with a layer of zinc, which provides a robust barrier against corrosion. This is crucial in marine environments where equipment is exposed to salty air and water.

- Durability: The galvanized coating adheres strongly to the steel, providing a durable and long-lasting protection.

- Maintenance: HDG steel requires less frequent maintenance compared to other materials that might corrode more quickly in a marine environment.

- Cost-Effectiveness: Galvanizing steel is often more cost-effective than using stainless steel or other high-cost corrosion-resistant materials.

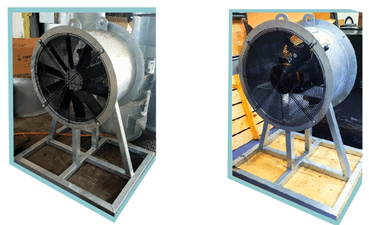

Regular inspections and maintenance are crucial for longer lifespan and ensure there is no mechanical damage.

Other Safety Measures and Test include

– Motors ATEX certification

– Routine Test Report

– Impeller Certificate of Conformation following ATEX Directive

– Motor Test Report

The Casing includes 2 lifting eyes for moving the FSE EX BUG BLOWER with lifting crane. As well as optional forklift pockets designed on bottom at the frame.

The wide frame and base designs ensures the fans in operation remain standing on floor and not easy to fall.

FSE Ex Bug Blowers are customised to meet applications. Customised design in size and CFM requirements as well as suitable to onboard power supply availability.

Loose EX DOL Starter can be supplied as optional additional.

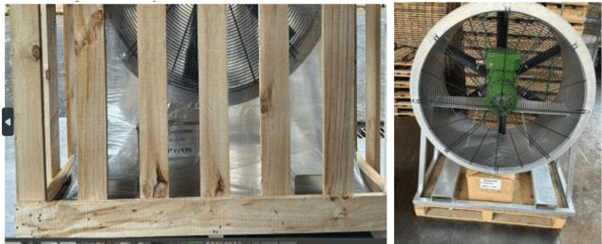

We also provide wooden crated sea-freight worthy export packing as optional extra if required, for safety during transit.

FSE Ex Bug Blowers standard sizes include 24″ and 36″ as well as most popular Ex Bug Blower 48″ / Ex Bug Blower 50″

Contact us for more information: Sales@fseprojects.com