ANTI FOULING SYSTEM

I.C.C.P System

System Configuration

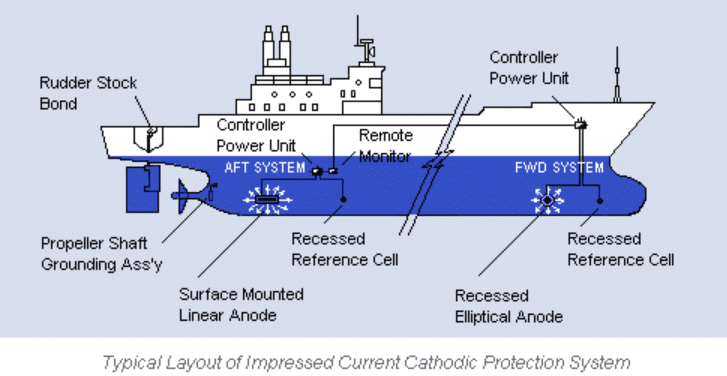

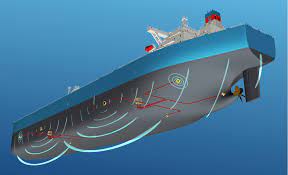

The ICCP system comprises an Automatic Control Power Unit, Anode, Reference Cell, Shaft Grounding Device, and Rudder Stock Grounding Cable.

- Automatic Controller Power Unit

The Automatic Controller Power Unit is a self-contained cabinet housing state-of-the-art solid-state circuitry with a printed circuit board. It offers two operation modes: Automatic and Manual. It transforms and rectifies the AC supply from the ship’s electrical system into a controlled DC output, ensuring optimal protection by distributing power to the anodes.

- Impressed Current Anodes

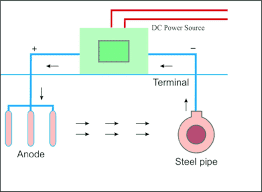

The feature platinum or MMO-coated carrier metal mounted on a resin holder, ensuring inertness and dimensional stability for extended service life. Anode types are chosen based on ship operation conditions and hull geometry. They conduct DC current through seawater to the hull, rendering it cathodic and safeguarding against corrosion.

- Reference Electrodes

It consists of a high-purity zinc block mounted in a resin holder, providing robustness and stable electrochemical characteristics ideal for referencing. These electrodes continuously measure hull potential and relay it to the power unit’s controller section, which adjusts current output accordingly.

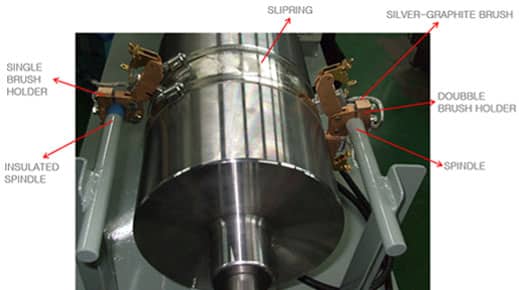

- Propeller Shaft Grounding

This Assembly guarantees solid electrical connection between the propeller, propeller shaft, and the ship’s hull. It achieves this by employing a silver-alloyed slip ring fixed to the hull structure, paired with silver graphite brushes in an adjustable holder. A shaft potential monitor tracks the grounding status and detects dirt and grease accumulation in the assembly.

- Rudder Stock Bonding Cable

It connects the rudder stock head to the deck head in the steering gear room, ensuring electrical continuity between the rudder and the hull for cathodic protection.

- Automatically delivers a direct current through anodes to protect underwater hull surfaces from corrosion.

- Utilizes cathodic polarization to effectively safeguard surfaces.

- Monitors and adjusts the hull-to-reference potential to maintain optimal protection.

- Applicable to diverse vessels such as ULCCs, small boats, offshore rigs, semi-submersibles, and other marine structures.

- Fully automatic operation maintains optimal hull potentials.

- Protects hull during coating deterioration.

- Extends intervals between dry dockings.

- Minimizes hull frictional resistance.

- Reduces maintenance time and costs.

- Safeguards propeller, propeller shaft, and rudder.

Shaft Grounding Device

System Configuration

- Digital Potential Meter:

- Battery-powered

- Digital display

- Simple installation and operation

- items & Installation

- High purity Silver Alloy Slip Ring

- Silver Graphite Brush & Holder

- When a vessel’s propeller rotates via the main engine, it generates a low constant current (mV), causing a potential difference with the hull and leading to propeller and shaft corrosion.

- Additionally, the dissimilar metals of propellers and shafts compared to the hull can induce corrosion due to ionisation tendencies. This minute current flowing into the shaft-based bearing system can potentially damage the main engine’s bearings.

- To address this issue, the Shaft Grounding Device compensates for these electrical currents. Suitable for all shaft sizes, it prevents corrosion and safeguards the bearing system from damage.

Anti Fouling System

The FSE SAFE Anti-Fouling System, also known as M.G.P.S., employs cutting-edge technology to prevent marine growth and biofouling on ship hulls. By utilizing a combination of magnetic and gas-producing substances, this system effectively deters the accumulation of organisms, reducing drag and enhancing fuel efficiency. FSE SAFE ensures optimal performance and protection, keeping vessels operating smoothly and reducing the need for frequent cleaning and maintenance.

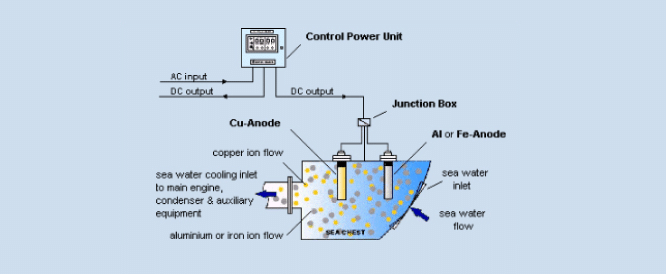

System Configuration

- Modular Constant Current Control Panel

Modular Constant Current Control Panel Features an anode module housing a transformer, power rectifier, electric current measuring, and control components. It provides two separate positive outputs, with current adjusted via a control knob and displayed numerically. Anomalies trigger a red LED indicator on the module and activate the alarm relay in case of power failure.

- Anti-Corrosion Anodes

The Anti-Corrosion Anodes are copper alloy rods supplied with a cofferdam and flange for easy replacement. When DC current is applied, the copper anode releases controlled copper ions into sea water circuits, preventing the settlement and development of primary forms of marine life.

- Prevents marine growth accumulation and reduces corrosion rates in sea water circulation systems.

- Achieves this through the controlled dissolution of copper, aluminum, or iron anodes via applied DC current.

- Applicable to commercial and naval vessels of various sizes, including ULCCs, small boats, offshore, and coastal facilities.

- Particularly beneficial for facilities using sea water for cooling and fire water purposes.

- Low capital expenditure and installation costs

- Easy installation and maintenance-free operation

- Prevention of main types of hard fouling

- Preservation of original design conditions for heat exchangers and seawater pumps

- Reduction of costly cleaning and maintenance for seawater cooling systems

- Minimal power consumption

- Environmentally acceptable usage