TOXIC & Oxygen GAS DETECTOR

Home / Products / Fire Gas Flame / Gas Flame / Toxic & O2 Gas Detectors

VECTOR- TOXIC

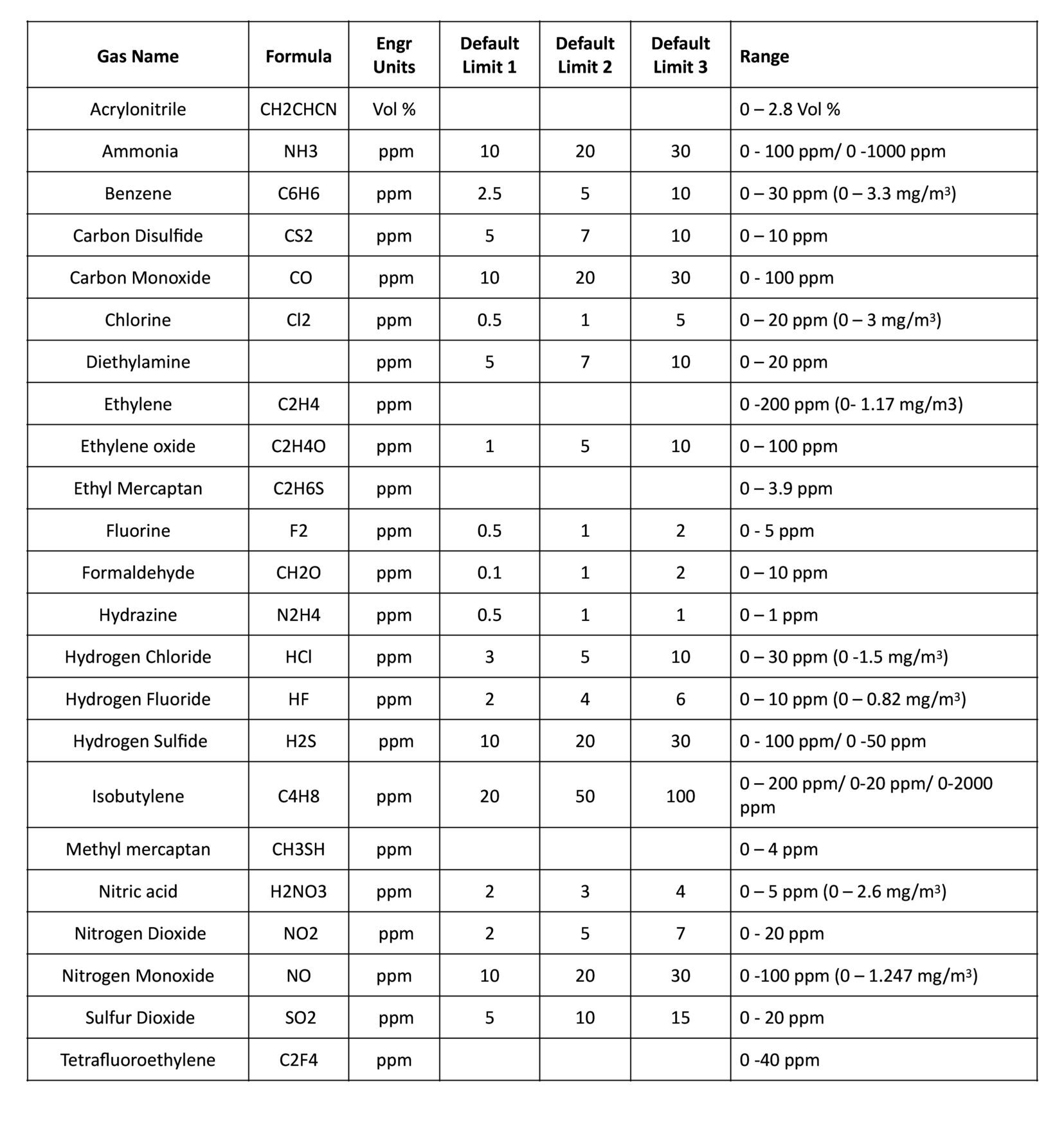

The Vector Toxic Gas Detector is a state-of-the-art device designed for the safe and efficient detection and monitoring of various toxic gases in the air. It is equipped to identify gases such as hydrogen sulfide, carbon monoxide, chlorine, nitric oxide, sulfur dioxide, and more. For a comprehensive list of detected gases, please refer to the “type of gases” tab on this page.

This versatile detector can be configured to monitor up to two sensors, either directly connected or remotely installed at a distance of up to 500 ft. The unit comes with multiple output options, allowing users to connect via 4-20mA, RS485, or relay for seamless communication with their system.

Featuring a user-friendly interface, the Vector simplifies the calibration process with on-site non-intrusive calibration through a local display or a HART handheld device. The on-board memory maintains an event log, storing calibration records and diagnostics for reference.

The vivid OLED display provides real-time information, including the type of gas, current concentration levels, and alarm status, ensuring quick and effective monitoring. The Vector Toxic Gas Detector is a reliable solution for organizations requiring precise gas detection capabilities with easy calibration and robust communication options.

- The system can be configured to accommodate two detectors, allowing for cost savings by monitoring two different gases in a single location or by utilizing one display to monitor two different locations.

- The Event Data Log, which is stored in the on-board memory, can be accessed either through the display or the RS-485 Modbus RTU.

- OLED screen, simultaneously displays a wide range of data including gas concentrations, alarm levels, faults and operational modes.

- 5 year warranty,Long product life with low cost to operate over time

Power Requirements: +24VDC Nominal (+18 to 32VDC)

Power Consumption: 4.3 W-standby; 5.3 W-during alarms; 12.0 W-w/ heater on (temp ≤ 30°F)

Signal Output From Vector FCU: 2X +4-20mA analog output, Digital RS-485 Modbus RTU, Relays, HART

Alarm Relays:

3 User Programmed Alarm Relays (factory default setting: NO)

1 Fault Condition Programmed Relay (factory default setting: NC)

Ingress Protection: IP66/67

Operating Temperature: -58°F to +167°C (-50°C to +75°C) -76°F to +167°C (-60°C to +75°C) with heater enabled

Storage Temperature: -76°F to +185°C (-60°C to +85°C)

Humidity Range: 0 to 100% relative humidity, non condensing

Conduit Connection: ¾” NPT

2 connections for Sensors

2 connections for Field Wiring

Enclosure Material: Stainless Steel (Grade 316)

Dimensions: 7.50” x 5.60” x 4.28″ (190.5mm x 142.24mm x 108.71mm)

Weight: Vector with one PGU attached – 14.00 lbs (6.35 kg)

- Offshore platforms

- Land rigs

- Shipping tankers, freighters, and other vessels

- LNG/LPG processing & storage facilities

- Oil & gas refineries

- Petrochemical plants

- Gas & electric utilities

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

VECTOR-OXYGEN

The cutting-edge Vector Oxygen Gas Detector, equipped with a convenient local display, is meticulously crafted for the secure detection and continuous monitoring of oxygen levels in various environments. Featuring an advanced electrochemical sensor, this device vigilantly observes the current oxygen concentration and promptly triggers an alarm if levels dip below the specified range.

This versatile detector can be customized to monitor up to two sensors, whether they are directly connected or strategically positioned up to a distance of 500 ft. To ensure seamless integration into your system, the unit is outfitted with multiple output options, including 4-20mA, RS485, or relay connections, ensuring reliable communication.

Setting a new standard in ease of use, the Vector simplifies the calibration process. Achieve precise calibrations effortlessly with on-site non-intrusive calibration through the local display or by utilizing an HART handheld device. The device’s on-board memory stores an event log, enabling it to maintain comprehensive calibration records and diagnostics for enhanced accuracy and performance tracking.

Power Requirements: +24VDC Nominal (+18 to 32VDC)

Power Consumption: 4.3 W-standby; 5.3 W-during alarms; 12.0 W-w/ heater on (temp ≤ 30°F)

Signal Output From Vector FCU: 2X +4-20mA analog output, Digital RS-485 Modbus RTU, Relays, HART

Alarm Relays:

3 User Programmed Alarm Relays (factory default setting: NO)

1 Fault Condition Programmed Relay (factory default setting: NC)

Ingress Protection: IP66/67

Operating Temperature: -58°F to +167°C (-50°C to +75°C) -76°F to +167°C (-60°C to +75°C) with heater enabled

Storage Temperature: -76°F to +185°C (-60°C to +85°C)

Humidity Range: 0 to 100% relative humidity, non condensing

Conduit Connection: ¾” NPT

2 connections for Sensors

2 connections for Field Wiring

Enclosure Material: Stainless Steel (Type 316L) or Aluminum

Dimensions: 7.50” x 5.60” x 4.28″ (190.5mm x 142.24mm x 108.71mm)

Weight: Vector with one PGU attached – 14.00 lbs (6.35 kg)

- Freezer chemical storage areas

- Prototyping and welding buildings

- General buildings

- Controlled labs for critical processes

- Analyzer rooms

- Confined rooms or areas.

Oxygen Detection Range: 0-30%v//v

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.

UPES

ESP Safety’s UPES Multi-Channel Controller provides users with exceptional flexibility, serving as a standalone rackmount control system or seamlessly interfacing with PLC or DCS systems. The advanced microprocessor-based monitoring system is designed to be compatible with all ESP Safety flame and gas detectors.

This versatile controller is offered in two variants: analog 4-20mA signal and digital RS485 signal. The analog version allows connection to up to 16 devices, utilizing the 4-20mA signal output from field devices. Meanwhile, the digital version accommodates up to 128 devices through the RS485 signal output.

Primarily used for monitoring and detecting gas concentrations and flame conditions in various facilities, the UPES triggers alarms when preset gas concentration thresholds are reached. Each alarm level is indicated by an LED, and there’s an optional sound alarm.

Beyond detection, the UPES serves as a centralized hub, linking detectors from the field to warning systems, automatic sprinklers, ventilation systems, and emergency shutdown controls. This integration enhances overall safety and control within the monitored environment.

Three (3) programmable alarm relays for each of the channels provide broad notification capability.

Compatible size,Modular measurement unit (3Ux19”) is compatible with industry standard size rack or stand-alone installation.

- Connect up to 128 devices via RS485 signal output

- Maximum number of data channels: 1-16 analog.

Input Voltage: 110VAC or 220VAC power supply and 24VDC from 18 to 32 VDC

Signal Outputs: RS-485 Modbus RTU compatible with PLC’s, SCADA, & DCS systems, 4-20 mA analog output, Relays (dry contact) with programmable alarm level and one relay for fault condition

Power Consumption: <300VA

U19 rack mount controller

Ingress Protection: IP54

Operating Temperature: -40°F to +158°F (-40°C to +70°C)

Storage Temperature:

Humidity: Up to 95%, Non-Condensing (withstands up to 100% reative humidity for short periods)

Dimensions: Width 19″ (482 mm); depth 9.3″ (266 mm); height 5.19″ (132 mm); standard block type 3U19”

Weight: 19lbs

- Drilling and production platforms

- Shipping tankers, freighters, and other vessels

- Fuel loading facilities

- Refineries, bulk terminals, and tank farms

- LNG/LPG processing and storage facilities

- Compressor stations and pipeline facilities

- Petrochemical, paint, and fertilizer plants

- Power plants and gas turbine facilities

- Transportation facilities (airports and subways)

- Oil and gas fired boilers / furnaces

- Environmental regulation monitoring

- The Ex Bug Blower Fans are dedicated to refining air quality and preventing intrusive insects.

- This versatile lineup comes in standard sizes with various power supply options, catering to a diverse range of industries.

- It offers a holistic approach to workplace well-being, emphasizing safety, comfort, and efficiency.

- The Ex Bug Blower 50 is the most popular choice, designed for deployment in both land-based and offshore drilling rigs.

- It provides reliable protection against flying insects and potentially hazardous down-hole gases.

- Available in standard sizes of 24, 36, and 48/50, with custom sizes also offered for adaptability.

- These bug blowers are indispensable for ensuring the safety and well-being of crew personnel in challenging environments.