Confined spaces present unique challenges for workers. Ensuring adequate lighting is crucial for safety and task completion, but introducing standard electrical equipment can be hazardous. That’s where low voltage confined space lighting comes in.

Why Low Voltage?

Standard line voltage (120V or 240V) poses a significant risk of electrocution in the potentially damp and conductive environment of a confined space. Even minor damage to a cable can have serious consequences.

Here’s where low voltage lighting shines (pun intended!):

Safety First: Low voltage (typically 12VAC or 24VAC) significantly reduces the risk of electric shock, even in wet conditions.

Compliance: Regulations like OSHA often mandate low voltage lighting for confined spaces.

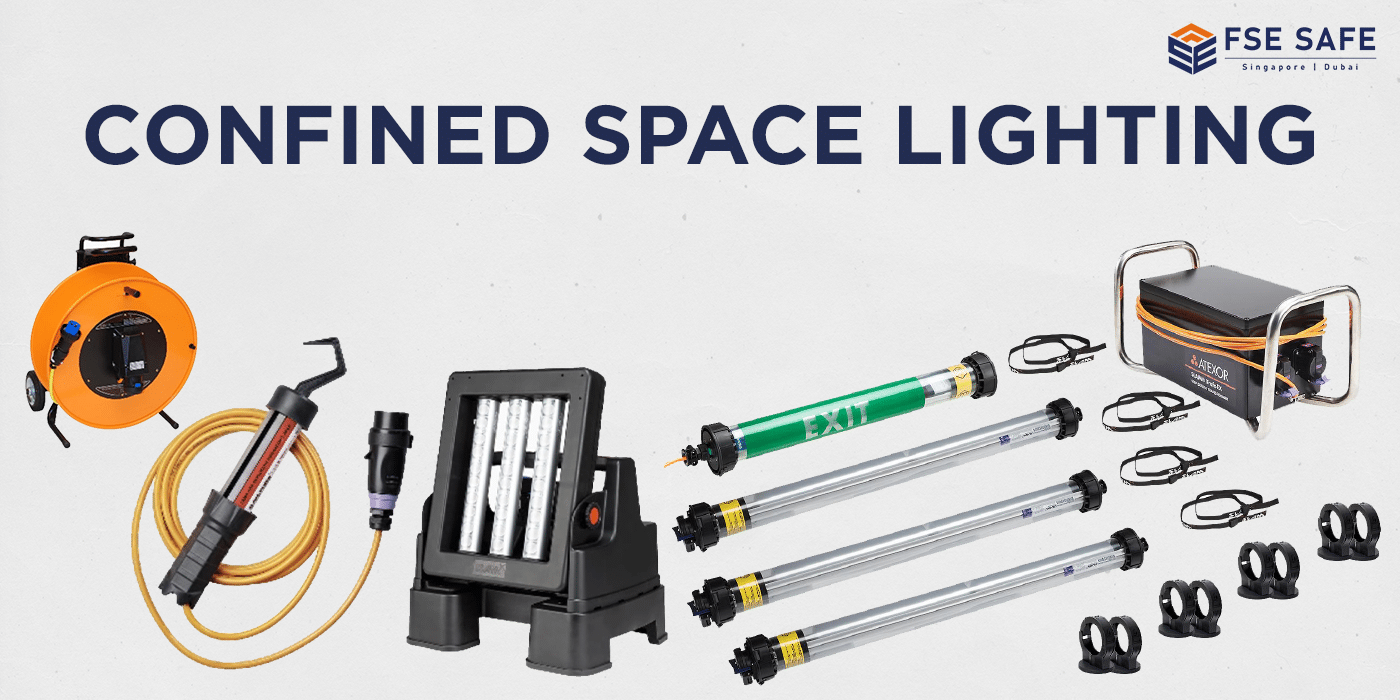

Types of Low Voltage Confined Space Lighting

Low voltage confined space lighting comes in various configurations to suit different needs and work environments. Here’s a breakdown of some common types:

1. Handheld Lights:

Flashlights: The most basic option, offering a focused beam for close-up inspection and maneuverability. Intrinsically safe flashlights are essential for flammable environments.

Headlamps: Provide hands-free illumination, ideal for tasks requiring both hands. Look for models with adjustable straps and beam angles.

2. Area Lights:

String Lights: Suspend these lightweight strings of multiple LED bulbs for general area lighting in larger confined spaces.

Work Lights: Sturdy, portable lights with stands or magnets for hands-free illumination and task lighting.

3. Specialized Lights:

Right Angle Lights: Designed for tight corners and hard-to-reach areas, these low-profile lights offer directional illumination.

Explosion-Proof Lights: A must-have for environments with flammable gas, dust, or vapors. These lights are encased in a specially designed housing to prevent sparks or ignition.

UV Lights: Useful for specific applications like leak detection or non-destructive testing in confined spaces.

Benefits of Low Voltage Confined Space Lighting:

Enhanced Safety: Reduced risk of electrocution protects workers.

Durability: Low voltage lights are often built tough to withstand harsh confined space environments.

Portability: Many low voltage lights are lightweight and compact, ideal for maneuvering in tight spaces.

Versatility: Available in various configurations (handheld, hanging, etc.) to suit different needs.

Efficiency: LED options provide bright illumination while minimizing power consumption.

Things to Consider When Choosing Low Voltage Confined Space Lighting:

Ingress Protection (IP) Rating: This rating indicates the light’s resistance to dust and water, crucial for confined space environments.

Lumens: Select a light that provides sufficient brightness for the specific task at hand.

Battery Life: For extended work periods, consider lights with long battery life or rechargeable options.

Explosion Proof Requirements: If the confined space has a risk of flammable gas or dust, explosion-proof lighting is necessary.

Safety Tips for Using Low Voltage Confined Space Lighting

Even with the inherent safety benefits, proper handling is crucial when using low voltage confined space lighting. Here are some key tips to remember:

Before Entering the Confined Space:

Inspect the Light: Ensure the light is in good working condition, with no cracks, damaged cords, or loose batteries.

Check the Battery: For battery-operated lights, make sure they are fully charged or have fresh batteries installed.

Verify Compatibility: If using explosion-proof lights, confirm their certification matches the specific hazardous atmosphere of the confined space.

While Using the Light in the Confined Space:

Mind the Cables: Keep cables away from potential snags or pinch points to prevent damage.

Avoid Submersion: While some lights may be water-resistant, avoid submerging them unless they have a specific waterproof rating.

Beware of Flammable Materials: Don’t place lights directly on flammable materials or expose them to excessive heat sources.

Maintain Communication: Stay in contact with the attendant outside the confined space and report any issues with the lighting.

Conclusion

Low voltage confined space lighting is an essential safety tool for workers operating in these demanding environments. By prioritizing safety, durability, and functionality, you can choose the right lighting solution to keep your team safe and productive. Contact FSE SAFE at [email protected]